3D Print results

It took some time to do the 3D prints!

Due to the configuration of the Ender3 v2 printer (calibration, fast, slow, scale), it took some time to get a 3D print. The model design didn’t give that many problems. But the print itself was the biggest problem. Basically: re-print with improved configurations, which retakes time, we didn’t do.

The photos are bad, I don’t have enough light.

Version 1

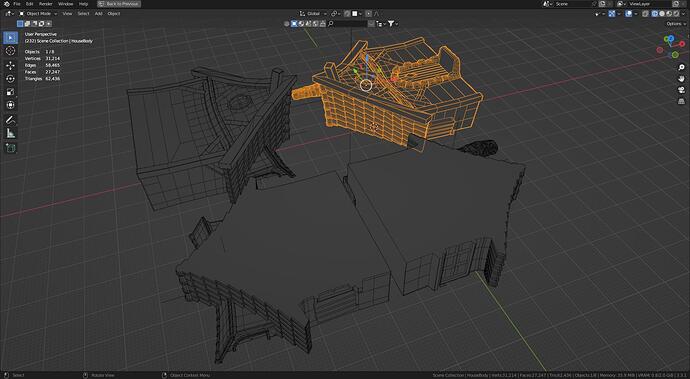

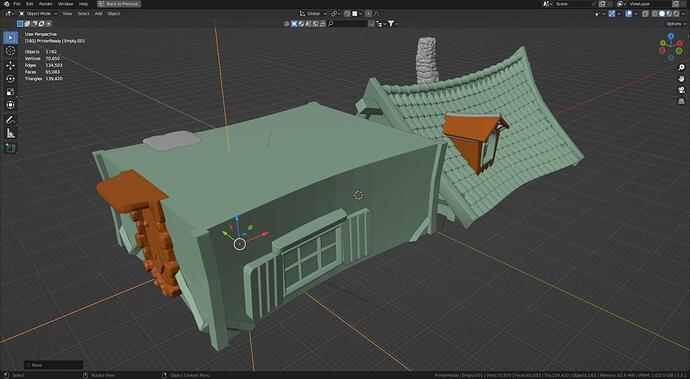

3D model

The idea was to use the flat glass surface to glue parts together seamlessly.

This didn’t work!

Problem was, due to the heat the print started to curl. Even with a print boundary.

Also, we detected that the glass plate wasn’t entirely flat.

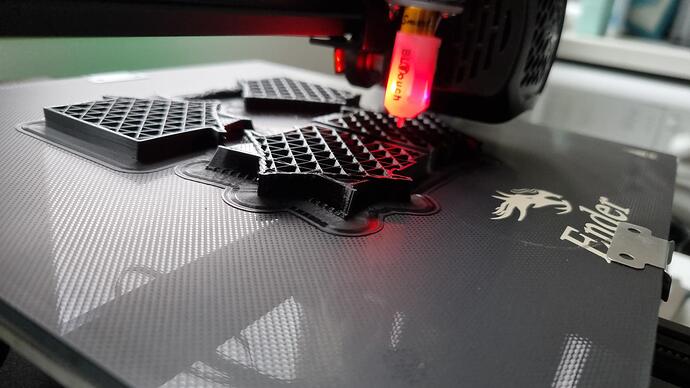

Print process

Glass plate (calibrated, not flat, it’s slightly dented) and still heat problems, bending the model.

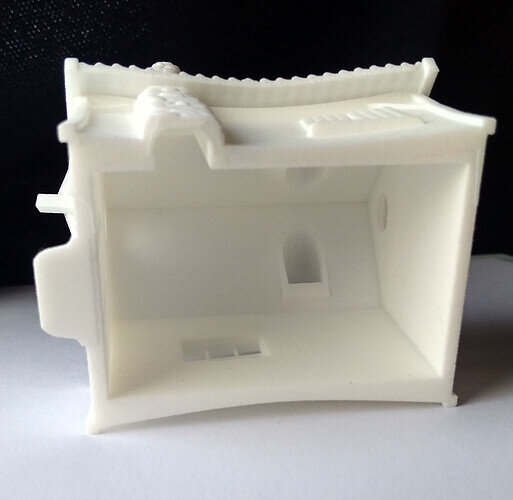

Glued together

Also, the vertical walls weren’t flat. For this, we need to try out the technique of “ironing” the surface, in a next print.

But It gives the house wall some nice texture. Not a big issue.

Good to see that the glued faces don’t match.

Strange artifacts on the vertical walls. Because they where printed horizontally. Because of the choice to print them in four parts.

A lot of cracks and spaces. For this to solve we need to do a lot of manual fixes. Or a reprint, hoping a new improved configuration will improve the outcome.

A funny outcome, is that the top surfaces (the middle one) are reasonable flat (nicely glued). While the four glass plate sides not!

Your nephew did a fantastic job at painting it.

Your nephew did a fantastic job at painting it.